For cost-effective operation and maintenance of pumping stations, a systematic approach to optimizing and analysing both the supply and demand sides of the system and how they interact, is key to total system performance. Riventa unlocks the full potential of assets to meet pumping station and network demand.

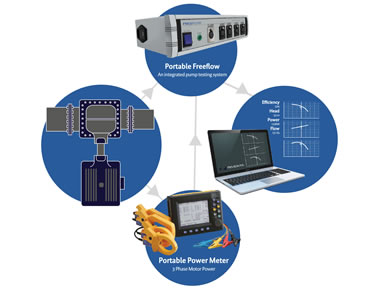

The FREEFLOW® pump testing system is designed to identify inefficient pumps and measure performance. The outcome is a coherent picture of the current asset stock and its contribution to service delivery.

However, pumping system characteristics can change with demand and station operation. Pump station monitoring allows pipeline owners to observe and control these changes. Often hidden characteristics are discovered that can lead to improvements in overall operating efficiency and pump lifecycle costs. The FREEFLOW® monitoring system is ideal for medium to large stations to optimise performance in relation to industrial pump stations, ECOFLOW® is an essential tool for real time performance in small to medium sized stations, while PROFLOW® is a specialist system for wastewater pump monitoring.

Using high quality data gathered via pump testing and monitoring, Riventa technology allows you to optimise your network, from a single service reservoir over a 24-hour period to sub-networks consisting of multiple pumping stations storage and demand.

Testing and monitoring the key parameters of pump efficiency, flow rate, head and electrical power and current pump performance characteristics allows pipeline owners to achieve best practice alignment and maximise the value of their pumps across there lifecycle.

- Maximise energy saving opportunities

- Increase pump efficiency and performance

- Analyse performance through quality data

- Predict, meet and improve network demand and performance

- Reduce risk, analyse corrective and preventative improvements